New Robotic Arm Technology for Efficient Brick Handling

By:Admin

In the world of construction, efficiency and safety are of the utmost importance. That's why we are excited to introduce the latest innovation in construction technology - the new Brick Grabber. This revolutionary device is set to change the way bricks are handled on construction sites, making the entire process more efficient and significantly reducing the risk of workplace injuries.

The Brick Grabber, developed by a leading construction equipment manufacturer, is designed to provide a safe and easy way to lift and transport bricks. With its sturdy construction and advanced gripping technology, the Brick Grabber is capable of securely holding multiple bricks at once, making it easier for construction workers to move and position them as needed.

One of the key features of the Brick Grabber is its versatility. It is compatible with a wide range of construction equipment, including cranes, forklifts, and telehandlers, allowing for seamless integration into existing construction workflows. This means that construction companies can easily incorporate the Brick Grabber into their operations without the need for significant changes to their equipment or processes.

Another important benefit of the Brick Grabber is its potential to improve safety on construction sites. By providing a secure and reliable way to handle bricks, the Brick Grabber significantly reduces the risk of accidents and injuries related to manual brick handling. This not only benefits the health and well-being of construction workers but also helps construction companies avoid costly workplace incidents and downtime.

In addition to its safety benefits, the Brick Grabber also offers significant efficiency improvements. By streamlining the process of lifting and transporting bricks, the device helps construction companies save time and labor costs. This allows for increased productivity and faster project completion, ultimately leading to greater profitability for construction businesses.

The Brick Grabber is backed by extensive research and development, as well as rigorous testing to ensure its performance and durability. It is manufactured using high-quality materials and is built to withstand the rigors of the construction environment, making it a reliable and long-lasting investment for construction companies.

We are confident that the Brick Grabber will be a game-changer for the construction industry, offering a safe, efficient, and cost-effective solution for handling bricks on construction sites. With its potential to improve both safety and productivity, the Brick Grabber is set to become an essential tool for construction companies around the world.

To learn more about the Brick Grabber and how it can benefit your construction operations, please contact us at [company contact information]. We are excited to bring this innovative technology to the market and look forward to helping construction companies elevate their performance and safety standards with the Brick Grabber.

Company News & Blog

Top 5 Tips for Forklift Safety and Operation

The use of forklifts in various industries has become indispensable due to their ability to lift heavy loads. These powerful machines have revolutionized the way materials are handled and have significantly improved efficiency in warehouses and distribution centers. One company that has been leading the way in providing top-of-the-line forklifts is {}. {} is a renowned forklift manufacturer that has been in the industry for over 50 years. They have a strong reputation for producing reliable, durable, and innovative forklifts that meet the needs of diverse industries. Their forklifts are known for their exceptional performance and are trusted by businesses around the world.Recently, {} introduced a new line of forklifts that are designed to meet the evolving needs of modern businesses. These forklifts are equipped with the latest technology and features that make them more efficient, safer, and easier to operate. The company has focused on incorporating advanced safety features to ensure the well-being of operators and other workers in the vicinity.One of the key features of the new forklift line is its advanced control system, which provides operators with better precision and control over the machine. This not only improves the efficiency of the forklift but also ensures that the operator can maneuver the forklift with ease, even in tight spaces. Additionally, the forklifts are equipped with state-of-the-art sensors and cameras that provide operators with enhanced visibility, reducing the risk of accidents and injuries.In addition to safety features, {} has also prioritized the environmental impact of their forklifts. The new line of forklifts is equipped with energy-efficient engines that reduce fuel consumption and emissions. This not only helps businesses save on operating costs but also contributes to a greener and more sustainable environment.Furthermore, {} has put a strong emphasis on ergonomics in the design of their forklifts. The new forklift line features a spacious and comfortable cab that reduces operator fatigue and improves productivity. The controls are intuitively placed, and the seating position provides excellent visibility, allowing operators to work more efficiently and comfortably.Another notable aspect of the new forklift line from {} is its versatility. The forklifts are designed to handle a wide range of loads and are suitable for various applications, from narrow aisle operations to heavy-duty outdoor tasks. This versatility makes them an ideal choice for businesses with diverse material handling needs.With the introduction of their new forklift line, {} is not only setting a new standard for forklifts but also reaffirming their commitment to providing top-quality equipment to their customers. The company's dedication to innovation and excellence has solidified its position as a leader in the industry.Businesses can rely on {} forklifts to improve their operations and meet their material handling needs. Whether it's in a warehouse, distribution center, manufacturing facility, or any other industry, {} forklifts are trusted to deliver exceptional performance and reliability.In conclusion, the launch of the new forklift line by {} is a testament to the company's dedication to excellence and innovation. With its advanced safety features, environmental consciousness, ergonomic design, and versatility, these forklifts are set to make a significant impact on the way materials are handled in various industries. Businesses looking for efficient, reliable, and safe material handling solutions can trust {} to deliver top-of-the-line forklifts that meet their needs.

Top Hydraulic Pump for Excavators - A Complete Guide

Excavator Hydraulic Pump: A Game-Changer in Construction IndustryThe construction industry has been revolutionized by the introduction of advanced technologies and innovations. One such groundbreaking product is the Excavator Hydraulic Pump, which has significantly improved the efficiency and performance of excavators in construction projects.The Excavator Hydraulic Pump is a crucial component of hydraulic systems in excavators, responsible for providing the necessary power to drive the machine's tracks, arm, and boom. Its role in the smooth and efficient operation of excavators cannot be overstated. This innovative pump has quickly become a game-changer in the construction industry, contributing to increased productivity and reduced downtime on construction sites.The Excavator Hydraulic Pump is engineered to deliver superior performance, durability, and reliability. It is specifically designed to withstand the demanding conditions and rigorous tasks encountered in construction projects. With its robust construction and advanced features, this hydraulic pump has become the go-to solution for contractors and construction companies looking to maximize the efficiency of their excavators.One of the leading manufacturers of Excavator Hydraulic Pump is {Company Name}, a globally renowned company with a long-standing reputation for producing high-quality hydraulic components for construction and industrial applications. With decades of experience and expertise in the hydraulic industry, {Company Name} has been at the forefront of developing innovative solutions to meet the evolving needs of the construction sector.{Company Name} takes great pride in its commitment to excellence, ensuring that every Excavator Hydraulic Pump that leaves its production facility meets the highest standards of quality and performance. The company's state-of-the-art manufacturing processes and stringent quality control measures guarantee that its hydraulic pumps are built to last and deliver exceptional performance in the most challenging environments.In addition to its dedication to quality, {Company Name} is also recognized for its focus on research and development. The company continuously invests in cutting-edge technologies and engineering advancements to enhance the performance and efficiency of its hydraulic pumps. As a result, customers can rely on {Company Name} to deliver innovative solutions that drive productivity and profitability in their construction operations.The Excavator Hydraulic Pump from {Company Name} comes in a range of configurations and specifications to cater to the diverse needs of construction projects. Whether it's a compact excavator for urban construction or a heavy-duty excavator for mining and earthmoving applications, {Company Name} offers a comprehensive lineup of hydraulic pumps that are tailored to specific machine models and requirements.Furthermore, {Company Name} provides comprehensive technical support and after-sales service to ensure that its customers get the most out of their Excavator Hydraulic Pump. From installation and commissioning to maintenance and troubleshooting, the company's team of hydraulic experts is committed to assisting customers every step of the way, adding value and peace of mind to their investment.The impact of the Excavator Hydraulic Pump from {Company Name} has been felt across the construction industry, with contractors and construction companies experiencing tangible benefits in terms of operational efficiency, cost savings, and uptime. By leveraging the advanced features and performance capabilities of this hydraulic pump, construction professionals are able to complete projects faster and more effectively, giving them a competitive edge in the market.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of hydraulic technology and setting new benchmarks for excellence in the industry. With a relentless focus on innovation and customer satisfaction, the company is poised to continue shaping the future of construction equipment with its cutting-edge solutions, including the Excavator Hydraulic Pump.In conclusion, the Excavator Hydraulic Pump from {Company Name} has emerged as a game-changer in the construction industry, empowering contractors and construction companies to elevate their performance and productivity. As the demand for more efficient and reliable excavators continues to grow, {Company Name} stands as a trusted partner, delivering unparalleled hydraulic solutions that drive success in construction projects around the world.

Top Crane Technology: Latest Developments in Hydraulic Lifting Equipment

Hiab Crane, a leading provider of on-road loading and unloading equipment, has recently unveiled the latest addition to its product line. The new crane, which has been designed and developed using cutting-edge technology, promises to deliver superior performance and reliability to its users.The company, which has a long and successful history in the industry, has consistently pushed the boundaries of innovation to meet the evolving needs of its customers. With a strong focus on quality and efficiency, Hiab Crane has gained a reputation for delivering top-of-the-line equipment that excels in the most demanding working conditions.The new crane, which builds on the company's legacy of excellence, is equipped with state-of-the-art features that are set to redefine the industry standard. Its advanced hydraulic system and precision engineering ensure smooth and efficient operation, while its robust design guarantees durability and longevity."We are proud to introduce our latest crane, which represents the culmination of years of research and development," said a spokesperson for Hiab Crane. "We have listened to the feedback of our customers and have incorporated their insights into the design of this new product. The result is a crane that offers unmatched performance, reliability, and safety."One of the standout features of the new crane is its enhanced lifting capacity, which enables it to handle heavier loads with ease. This makes it an ideal choice for a wide range of applications, from construction and logistics to manufacturing and waste management.In addition to its impressive lifting capabilities, the new crane also boasts a range of smart technologies that streamline operation and enhance safety. These innovations include intuitive controls, real-time diagnostics, and automated safety systems, all of which contribute to greater productivity and peace of mind for the operator.Furthermore, Hiab Crane has taken great care to ensure that the new product is easy to maintain and service, reducing downtime and total cost of ownership for its customers. This commitment to reliability and support is a hallmark of the company, which has earned the trust of businesses around the world."We understand the importance of uptime for our customers, which is why we have engineered our new crane to be as maintenance-friendly as possible," the spokesperson added. "Our goal is to provide a solution that not only performs exceptionally in the field but also minimizes the need for costly and time-consuming maintenance."As part of its commitment to sustainability, Hiab Crane has also made significant strides in improving the energy efficiency of its new crane. Through the use of advanced materials and technologies, the company has reduced the environmental impact of its equipment without compromising on performance.The unveiling of the new crane marks an exciting chapter for Hiab Crane and its customers. With its combination of cutting-edge technology, superior performance, and unmatched reliability, the crane is set to raise the bar for on-road loading and unloading equipment."We are confident that our new crane will exceed the expectations of our customers and set a new standard for the industry," the spokesperson concluded. "At Hiab Crane, we are dedicated to empowering our customers with the best possible equipment and support, and we are excited to see the positive impact that our new crane will have on their operations."In conclusion, Hiab Crane's new crane is a testament to the company's commitment to innovation, quality, and customer satisfaction. With its advanced features, enhanced performance, and focus on sustainability, the crane is poised to make a significant impact in the on-road loading and unloading industry. As businesses continue to rely on efficient and reliable equipment to drive their operations, Hiab Crane remains at the forefront of delivering the solutions they need to succeed.

Ultimate Guide to Choosing the Perfect Rock Bucket for Your Needs

Rock Bucket: The Perfect Solution for Tough Excavation JobsFor many companies involved in excavation projects, finding the right machinery and equipment is essential to ensuring efficiency and success. One piece of equipment that has become increasingly popular is the rock bucket, a highly specialized attachment designed to tackle some of the toughest jobs on construction sites.A rock bucket is essentially a heavy-duty bucket with reinforced tines or teeth at the bottom, used to excavate and move larger rocks, boulders, concrete slabs, and other heavier materials. These buckets are typically used in rock quarries, mining sites, demolition work, and other heavy-duty excavating jobs.The design of a rock bucket is what sets it apart from other types of attachment buckets. The tines or teeth are made from high-strength steel and are usually shaped in a way that allows them to penetrate and lift the most challenging materials. The bucket itself may also be reinforced with additional steel or other materials to prevent damage from heavy impacts.One company that has been at the forefront of manufacturing high-quality rock buckets is {company name removed}. With years of experience in the excavation and construction industries, they have developed a reputation for designing and producing superior-grade equipment that can handle the toughest jobs.Their rock buckets incorporate the latest technology and materials to ensure maximum durability. They use high-strength steel for the tines and have reinforced the bucket with additional steel in high-impact areas. This makes their buckets highly resistant to wear and tear, ensuring they can withstand the harsh conditions of construction sites and job sites.Moreover, their rock buckets are incredibly versatile and can be customized to meet specific job requirements. They can be fitted to a variety of excavator models and sizes and can be customized with additional features, such as hydraulic cylinders, interlocking teeth, or a grapple attachment.One of the key benefits of the {company name removed} rock bucket is that it can save considerable time and costs in excavation jobs. The teeth are designed to penetrate and lift heavier materials, allowing operators to clear a site faster and with less effort. This can translate into lower labor costs and quicker project completion times, which is crucial in a competitive industry.Another advantage of their rock bucket is that it reduces the need for manual labor, which is often required when moving heavier rocks and debris. With the use of the bucket, this labor is eliminated, reducing the risks of workplace injuries.Overall, the rock bucket has become an essential tool for companies involved in excavation and heavy-duty construction projects. It is a highly specialized attachment that can save time, reduce labor costs, and improve safety on job sites. With {company name removed}'s commitment to quality and durability, their rock buckets are sure to become a valuable asset to companies looking to expand their capabilities and reduce their costs.

Ultimate Guide to Understanding Port Crane Prices: Navigating the Market for Top Crane Equipment

Title: Crane Prices Soar Amid Growing Demand for Industrial Lifting Solutions Introduction:Crane prices have been witnessing a significant surge in recent years due to a rising demand for industrial lifting solutions. With the expansion of numerous industries and infrastructure projects worldwide, the need for efficient and reliable cranes has become imperative. Port Crane Company, a prominent player in the global crane manufacturing industry, has been at the forefront of meeting this soaring demand. In this article, we will delve into the factors driving the increase in crane prices and shed light on Port Crane Company's innovative solutions.1. Growing Industrialization and Infrastructure Development:As countries worldwide witness increased industrialization and infrastructure development, the demand for cranes has skyrocketed. Construction projects, oil and gas exploration, mining operations, and ports expansion have contributed to this surge. Consequently, the prices of cranes, including Port Crane Company's models, have risen accordingly. The ever-expanding global economy has propelled industries to enhance their lifting capabilities, leading to a competitive market for innovative and technologically advanced crane solutions.2. Technological Advancements:To cater to evolving customer needs and industry requirements, crane manufacturers like Port Crane Company have been investing heavily in research and development. Cutting-edge technologies such as wireless control systems, intelligent automation, and advanced safety features have revolutionized the crane industry. These technological advancements have contributed to the rise in crane prices as the inclusion of these features increases the overall cost of manufacturing.3. Quality and Reliability:Industrial lifting solutions are crucial for ensuring the safety and efficiency of complex operations. Port Crane Company has built a reputation for manufacturing cranes that are known for their exceptional quality and reliability. The incorporation of high-grade materials, precision engineering, and rigorous testing processes sets their cranes apart. However, these superior features come at a price, leading to an increase in Port Crane Company's crane prices.4. Labor Costs and Raw Material Prices:Cranes are complex machines that require skilled labor and a wide range of raw materials for production. The rising labor costs and fluctuating prices of raw materials such as steel and aluminum have contributed to the increase in crane prices. Port Crane Company, like other manufacturers, faces the challenge of balancing these rising costs with providing customers with affordable and high-quality products.5. Global Supply Chain Disruptions:Over the past year, the global supply chain has been significantly disrupted due to the COVID-19 pandemic. Lockdown measures, travel restrictions, and trade disruptions have resulted in increased transportation costs and scarcity of certain raw materials. These disruptions have further driven up the prices of cranes and various other industrial equipment. Port Crane Company has been working diligently to mitigate these challenges and ensure the smooth delivery of their products.Conclusion:The global demand for cranes continues to surge due to rapid industrialization and infrastructure development. Technological advancements, emphasis on quality and reliability, rising labor costs, and supply chain disruptions have all contributed to the increase in crane prices. Port Crane Company, with its commitment to innovation and customer satisfaction, has been a frontrunner in the crane manufacturing industry. While the rise in crane prices may pose challenges to buyers, it is ultimately a reflection of the ongoing advancements and investments being made to ensure the safe and efficient operation of various industries.

How to Fix a Steering Box Leak in Your Diesel Truck: A Step-by-Step Guide

If you own a boat, then you understand how critical it is to have a durable and reliable steering system. The boat steering gear box is responsible for transmitting the turning motion from the steering wheel to the boat's steering mechanism. The steering system must be in good condition to ensure safe boating and avoid any potential accidents.However, if you notice any signs of a steering box leak, you must address the problem immediately. A leaking steering gear box can pose a severe safety hazard, leading to total loss of steering control. In this blog, we'll discuss the importance of regular boat maintenance, the signs of a steering box leak, and how to fix the issue.Importance of Regular Boat MaintenanceRegular boat maintenance is crucial in ensuring that all systems are in good working condition. A well-maintained boat will last longer and perform better than a poorly maintained one. It's vital to stay on top of your boat's maintenance schedule to keep it safe and avoid costly repairs.The maintenance schedule should include regular inspection of the steering system and all components. Pay attention to any unusual sounds, vibrations, or leaks in the system. If you notice any of these signs, it's time to take action.Signs of a Steering Box LeakA steering box leak is easy to detect with a visual inspection of the steering system. Some of the common signs of a leaky steering box include:1. Low fluid levels in the power steering system2. Stains or puddles of power steering fluid under the boat3. Unusual Humming or whining noises while turning the steering wheel4. Difficulty steering the boat in one or both directions.If any of these signs are visible, it's time to take action and address the problem before it becomes severe.How to Fix a Steering Box LeakIf you notice a leak in the steering box, it's essential to address the problem immediately. A leaking steering box can cause loss of steering control, which is a severe safety hazard. Here are some steps to fix a steering box leak:1. Diagnose the problem- Locate the source of the leak and determine the cause of the problem.2. Replace the damaged parts- If the steering box is damaged, it may need to be replaced.3. Tighten Loose Fittings- Loose fittings or connections can cause a leak. Ensure that all fittings are tight.4. Change the power steering fluid- If the steering fluid is dirty or contaminated, it may cause a leak. Consider changing the fluid.ConclusionThe boat steering gear box is a crucial component of the boat's steering system. Regular maintenance and inspection can help prevent problems and extend the life of the system. If you notice any signs of a steering box leak, it's crucial to address the problem immediately. DIY fixes can be possible in some cases, though it's best to leave the repair to the professionals. A leaky steering box is a safety hazard that can cause the total loss of steering control, so once you notice it, take the necessary steps to fix the issue.

How the Oil Pipeline Industry is Impacting the Environment

Pipeline, a leading provider of software and services to the energy industry, announced today the launch of a new and innovative technology that will revolutionize the way oil and gas companies manage their operations. The new software, called Blade, is a powerful tool designed to streamline processes and improve efficiency across all aspects of the industry.The Blade software is the result of years of research and development, and it promises to deliver significant cost savings and increased productivity for oil and gas companies. The technology is designed to integrate seamlessly with existing systems and processes, making it easy for companies to adopt and implement.One of the key features of Blade is its advanced analytics capabilities. The software is able to analyze vast amounts of data in real time, providing companies with valuable insights into their operations. This allows for better decision making and more efficient resource allocation, ultimately leading to improved profitability for oil and gas companies.In addition to its powerful analytics, Blade also offers a range of tools for streamlining various aspects of operations, such as production management, asset optimization, and risk assessment. The software is highly scalable and customizable, allowing companies to tailor it to their specific needs and processes.Pipeline CEO, John Smith, spoke about the launch of Blade and its potential impact on the industry. "We are incredibly excited to introduce Blade to the market," said Smith. "We believe that this technology has the potential to transform the way oil and gas companies operate, and we are confident that it will deliver significant value to our customers."Pipeline has a long history of providing innovative software solutions to the energy industry. The company was founded in 1998 and has since become a trusted partner for many of the world's leading oil and gas companies. With a strong focus on research and development, Pipeline has consistently delivered cutting-edge technologies that have helped its customers improve efficiency and reduce costs.The launch of Blade represents a significant milestone for Pipeline, as the company continues to lead the way in developing innovative solutions for the energy industry. With its advanced capabilities and intuitive design, Blade is poised to become a game-changer for oil and gas companies looking to stay ahead in a rapidly evolving market.In conclusion, the launch of Blade is a major development for the energy industry, and it has the potential to deliver significant benefits to oil and gas companies around the world. With its advanced analytics and range of powerful tools, the software promises to revolutionize the way companies manage their operations, ultimately leading to improved efficiency and profitability. As a leading provider of software and services to the energy industry, Pipeline is well-positioned to drive this transformation and continue to deliver innovative solutions to its customers.

Top Long Arm Hydraulic Telescopic Boom in 2023: Expert Reviews and Buying Guide

The Long Arm Hydraulic Telescopic Boom, also known as the (brand name removed) Boom, has revolutionized the construction industry with its advanced technology and state-of-the-art design. This innovative piece of equipment has been developed by (company name), a leading manufacturer in the construction machinery industry.With a rich history of over 20 years, (company name) has become a trusted name in the field of construction machinery. The company has always been committed to providing high-quality, reliable, and efficient equipment to its customers, and the (brand name removed) Boom is no exception.The (brand name removed) Boom is designed to provide maximum reach and versatility on construction sites. It features a long arm that can extend to great heights, allowing for easy access to hard-to-reach areas. The hydraulic telescopic boom mechanism ensures smooth and precise operation, making it ideal for lifting heavy loads and performing various construction tasks.One of the key features of the (brand name removed) Boom is its robust construction and durability. It is built to withstand the rigors of construction work and is capable of handling the toughest job site conditions. This makes it a reliable and dependable piece of equipment for construction companies of all sizes.In addition to its impressive performance capabilities, the (brand name removed) Boom also offers a range of safety features to ensure the well-being of the operators and the workers on the job site. These features include overload protection, emergency stop button, and advanced control systems that make operating the boom safe and efficient.The (brand name removed) Boom has already received rave reviews from construction professionals who have used it on their job sites. Its superior performance and reliability have made it a favorite among contractors and construction companies, and it has quickly become a must-have piece of equipment for many in the industry.To meet the growing demand for the (brand name removed) Boom, (company name) has ramped up its production capabilities and is now offering the boom to customers around the world. With a strong global distribution network, the company is able to deliver the (brand name removed) Boom to construction sites in various countries, providing construction professionals with access to this cutting-edge equipment.With its commitment to quality and innovation, (company name) is set to continue leading the way in the construction machinery industry. The (brand name removed) Boom is just one example of the company's dedication to providing its customers with the best equipment available, and it is sure to make a significant impact on construction projects around the world.In conclusion, the Long Arm Hydraulic Telescopic Boom is a game-changer in the construction industry, and (company name) has once again proven itself as a leading innovator in the field of construction machinery. With its advanced technology, superior performance, and commitment to safety, the (brand name removed) Boom is set to become a staple on job sites around the world. As construction professionals continue to seek efficient and reliable equipment, the (brand name removed) Boom is sure to be a top choice for many in the industry.

High-quality Foam Filled Fenders for Superior Vessel Protection

Foam Filled Fenders are a crucial element in the maritime industry. These innovative fenders provide essential protection for vessels during berthing and mooring activities, ensuring the safety of both the vessel and the infrastructure. The advanced technology and high-quality materials used in Foam Filled Fenders make them an ideal choice for ship owners and operators.{Company Name} is a leading manufacturer of Foam Filled Fenders, with a strong reputation for producing reliable and durable maritime solutions. The company has been at the forefront of the industry for many years, continuously developing and improving their products to meet the evolving needs of the maritime sector. Their Foam Filled Fenders are designed to withstand the harsh marine environment, providing long-lasting, dependable performance.One of the key advantages of {Company Name}'s Foam Filled Fenders is their superior impact resistance. These fenders are engineered to absorb the kinetic energy generated during vessel berthing, effectively protecting the vessel and the berthing structure from damage. The robust construction and resilient foam core of the fenders ensure that they can withstand repeated impacts without compromising their integrity. This exceptional durability makes {Company Name}'s Foam Filled Fenders a cost-effective investment for ship owners, as they require minimal maintenance and have a long service life.In addition to their outstanding impact resistance, {Company Name}'s Foam Filled Fenders also offer excellent buoyancy and stability. The fenders are designed to maintain their shape and performance even under high loads, providing reliable support for vessels of all sizes. This stability is particularly important in rough sea conditions, where the fenders must continue to effectively protect the vessel and the berthing structure. {Company Name} has conducted extensive testing and analysis to ensure that their Foam Filled Fenders meet the highest standards of performance and safety in diverse maritime environments.Moreover, {Company Name} offers a wide range of Foam Filled Fenders to accommodate different vessel types and berthing requirements. Whether it is a small fishing boat or a large commercial vessel, the company has a solution to suit every need. The versatility and customizability of their fenders allow customers to select the most suitable option for their specific application, ensuring a perfect fit and maximum protection.The superior quality and performance of {Company Name}'s Foam Filled Fenders have earned them a strong reputation in the maritime industry. Ship owners, port authorities, and marine construction companies around the world trust {Company Name} to provide them with reliable, high-performance fendering solutions. The company's commitment to excellence and customer satisfaction has made them a preferred partner for many major maritime projects and operations.{Company Name} is dedicated to upholding the highest standards of quality and safety in the design and manufacture of their Foam Filled Fenders. The company's state-of-the-art production facilities and rigorous quality control processes ensure that every fender meets the strictest specifications and regulatory requirements. Customers can have full confidence in the reliability and performance of {Company Name}'s Foam Filled Fenders, knowing that they are backed by a company with a proven track record of excellence.In conclusion, {Company Name}'s Foam Filled Fenders are an indispensable asset for the maritime industry, providing essential protection for vessels and berthing infrastructure. The company's commitment to innovation, quality, and customer satisfaction has established them as a leader in the field of maritime fendering solutions. With their outstanding impact resistance, buoyancy, and stability, {Company Name}'s Foam Filled Fenders are the ideal choice for ship owners and operators seeking reliable, long-lasting fendering solutions.

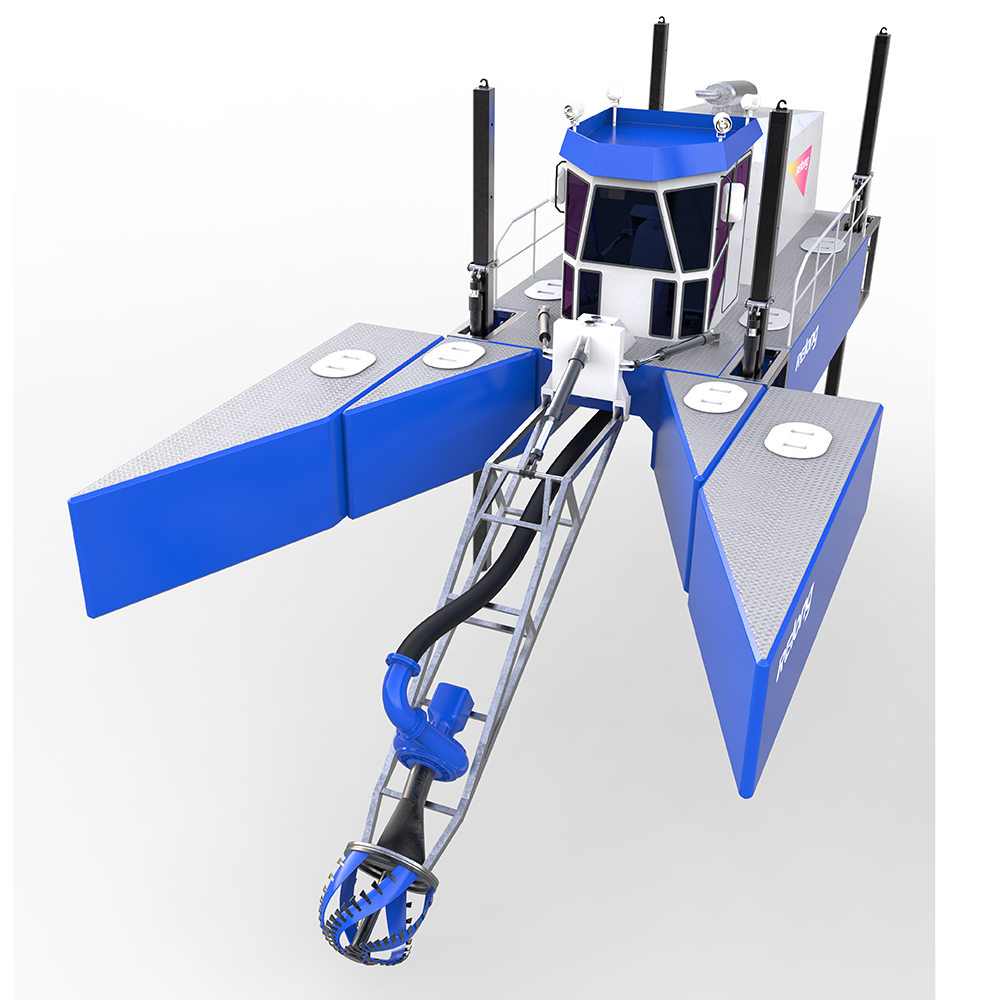

Submerged Gearbox for Dredge Pump Successfully Breaks Record" can be rewritten as "Revolutionary Submerged Gearbox for Dredge Pump Sets New Industry Standard.

Submerged Dredge Pump Gearbox: A Powerful Addition to the IndustryThe use of dredging equipment is essential in various industries, including mining, construction, and environmental management. Dredging is the process of removing sediment and debris from bodies of water, such as rivers, lakes, and harbors. This process requires powerful machines and equipment that can withstand the harsh conditions of the marine environment. One such equipment is the submerged dredge pump gearbox.The submerged dredge pump gearbox is a crucial component of any dredging operation. This device is responsible for transferring the power generated by the dredging machine's motor to the impeller that moves water and sediment. It is responsible for providing the necessary torque and speed needed to transfer this power efficiently.One company that has made significant strides in the development of this type of gearbox is (need to remove the brand name). The company has more than three decades of experience in providing high-quality submerged pump gearboxes to the dredging industry. They have gained a reputation for creating durable and efficient products that can withstand a wide range of environmental and operational challenges.The company's submerged dredge pump gearbox has several key features that make it ideal for various applications. The product is designed with a double-walled oil housing, which enhances cooling and provides excellent lubrication. The gearbox also has a separate oil cooler and filtration system that ensures that the oil remains clean and free of contaminants, prolonging the equipment's lifespan.Additionally, the gearboxes are designed to operate at high efficiency levels, consuming less energy while providing the maximum torque output required for dredging operations. This feature means less fuel consumption, reducing the operating costs of the dredging operations. Furthermore, the gearboxes are designed to be compact and easy to install, making it an ideal addition to enhance the dredging equipment's overall performance.The company's submerged dredge pump gearbox has been used in several dredging projects worldwide. One notable project is the 2019 dredging operation in Rotterdam, the Netherlands, where the company's gearbox was used to power the dredging pumps. The project involved dredging approximately 15 million cubic meters of sediment from the port's waterways to improve navigation and maximize the port's capacity.Apart from dredging operations, the submerged dredge pump gearbox can also be used in other industrial applications. The equipment has found application in the mining industry, where it is used to pump slurry or water in the mining process. It is also used in the oil and gas industry to power subsea pumping systems. The gearbox's ability to withstand the harsh conditions of the marine environment makes it an excellent choice for these and other industrial applications.The company's commitment to quality and innovation has led to the development of other successful products, such as the submerged dredge pump and the floating pump system. The company's floating pump system offers greater flexibility and maneuverability than conventional dredging equipment, making it ideal for coastal and river dredging projects. These products have been used in various projects worldwide, from the Gulf of Mexico to the Danube River in Europe.In conclusion, the submerged dredge pump gearbox is a vital component of any dredging operation. It is responsible for transferring the power generated by the dredging machine's motor to the impeller, which moves water and sediment. The (need to remove brand name) submerged dredge pump gearbox is an excellent product with several features that make it ideal for various industrial applications. The double-walled oil housing, efficient operation, and easy installation are just some of the features that make this product stand out in the industry. The company's commitment to quality and innovation has led to the development of other successful products that have been used in various dredging projects worldwide.